Silicon Carbide Products

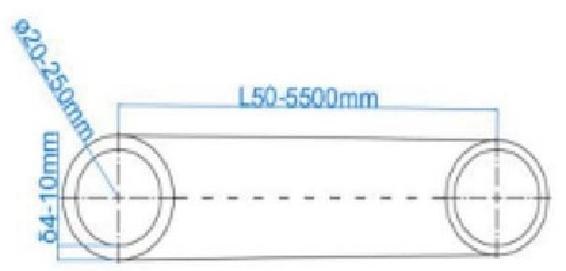

Silicon carbide products, a high-quality silicon carbide refractory material, are made mainly from high-quality silicon carbide as the main raw material by using a reasonable strength ratio, adding high-temperature sintering agents, and firing at high temperatures. Silicon carbide rollers have the characteristics of excellent high-temperature bending strength, oxidation resistance, corrosion resistance and strong wear resistance. They will not be broken or bended after long-term high-temperature use. They are widely used in roller kilns for the production of lithium battery positive and negative electrode materials, photovoltaic equipment, magnetic materials, daily ceramics, architectural ceramics, etc